Technology

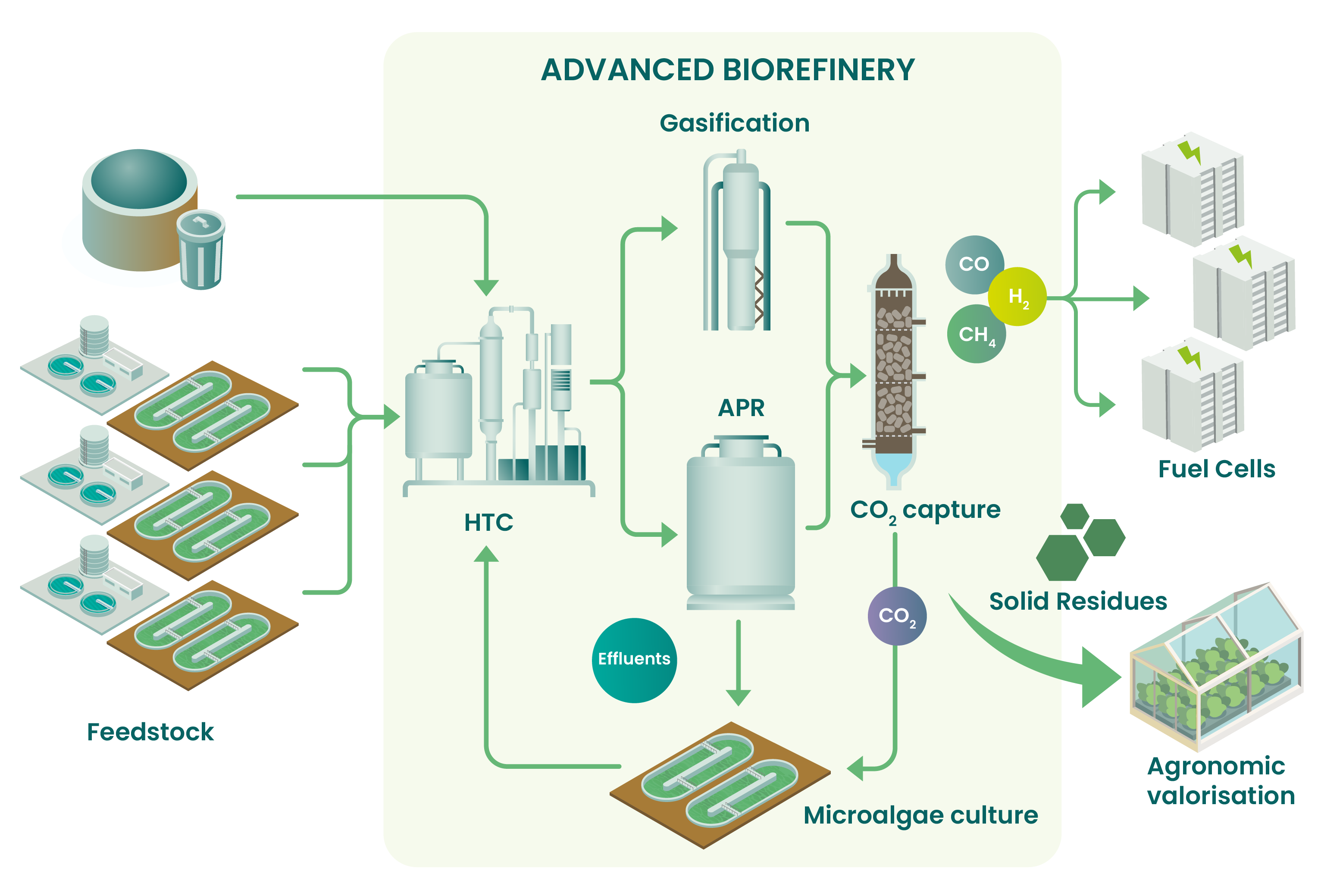

NIAGARA aims to develop and demonstrate at TRL4 a reliable process to produce sustainable advanced biofuels from biogenic wastes and microalgae

1

- Microalgae will be cultivated both at wastewater treatment plants and centralized facilities.This allows to process microalgae at a central location, while also recycling waste from the conversion process back into microalgae growth.

- The microalgae biomass and the biogenic wastes will be transported to an integrated

advanced biorefinery where the HTC, APR and gasification processes are located.

2

- HTC is thermochemical conversion performed in a wet environment, and thus well adapted for feedstock with a high-water content.

- The main product resulted from this process is a solid carbonaceous residue, called hydrochar.

3

- The leftover liquid from HTC will go through aqueous phase reforming (APR) to produce more biofuel gases like hydrogen and alkanes, maximising gas production.

4

- Hydrochar will be converted into gas through gasification, producing syngas (biofuel).

5

- The CO2 produced during the upstream processes will be recycled to the microalgae through a CO2 capture step using an innovative sorbent.

- The remaining nutrients will be used for microalgae production. The gasification’s solid residues will be tested for agronomic valorisation to reach a no-waste policy (as fertilizer and/or soil amendment).

6

- Making the syngas compatible with SOFC for efficient electricity production.

- SOFC will be tested over a wide range of the relevant bio-syngas mixtures specifically with respect to carbon deposition and the presence of impurities.

7

- Using e.g. artificial intelligence tools and multicriteria optimisation.